When embarking on a construction project like framing bedrooms in a barndominium, selecting the right 2×4 wood is critical for ensuring structural integrity, cost-efficiency, and ease of work. The term “2×4” refers to dimensional lumber with a nominal size of 2 inches by 4 inches, though actual dimensions are 1.5 inches by 3.5 inches after milling. With various wood species, grades, and treatments available, understanding their differences is essential for choosing the best option for your non-load-bearing framing needs. This comprehensive guide explores the types of 2×4 wood, their properties, applications, and recommendations for framing, tailored to optimize your project’s success.

What is 2×4 Wood?

2×4 wood is a staple in construction, used primarily for framing walls, roofs, and floors. It’s categorized as dimensional lumber, meaning it’s cut to standardized sizes for consistency across projects. For non-load-bearing applications, such as interior partition walls in a barndominium, 2x4s provide sufficient strength while being cost-effective and easy to handle. The choice of wood type, grade, and treatment impacts durability, workability, and aesthetics.

Common Types of 2×4 Wood

2×4 lumber is typically softwood, as it’s more affordable and widely available than hardwood. The most common species used for 2x4s include Spruce-Pine-Fir (SPF), Southern Yellow Pine (SYP), Whitewood, Douglas Fir, and Hemlock. Below is an in-depth look at each, focusing on their characteristics and suitability for framing.

1. Spruce-Pine-Fir (SPF)

SPF is a grouping of softwood species, including spruce, pine, and fir, often sold together due to similar properties. It’s one of the most common choices for 2×4 framing lumber.

Characteristics:

- Color: Light, ranging from white to pale yellow.

- Density: Moderate, lighter than SYP or Douglas Fir, making it easier to handle.

- Grain: Contains knots and blemishes, which can affect appearance but not structural integrity for non-load-bearing walls.

- Workability: Easy to cut, nail, and screw, with minimal splitting compared to harder woods like Hemlock.

- Warping: Prone to warping if not properly dried or stored, requiring careful selection.

Applications:

- Ideal for interior framing, such as partition walls, where aesthetics are less critical.

- Commonly used in residential construction due to its availability and affordability.

Pros:

- Cost-effective, often the cheapest 2×4 option.

- Lightweight, reducing fatigue during installation.

- Widely available at big-box stores and lumberyards.

Cons:

- Susceptible to warping and twisting if not kiln-dried properly.

- Lower strength compared to SYP or Douglas Fir, though sufficient for non-load-bearing walls.

Price (Approximate): $3.50–$5.00 per 8-foot stud (varies by region and supplier).

2. Southern Yellow Pine (SYP)

Southern Yellow Pine is a dense, strong softwood native to the southeastern United States, known for its durability and straightness.

Characteristics:

- Color: Yellowish with a distinct grain pattern.

- Density: High, making it heavier and stronger than SPF.

- Grain: Clearer and straighter than SPF, with fewer knots in higher grades.

- Workability: Harder to cut and nail due to density, but provides a robust nailing surface.

- Warping: Less prone to warping than SPF when properly kiln-dried.

Applications:

- Suitable for both load-bearing and non-load-bearing framing, though its strength makes it overkill for partition walls.

- Popular in regions east of the Rockies, where it’s readily available.

Pros:

- Straighter and clearer than SPF, reducing the need to cull warped pieces.

- Stronger, offering durability even in non-structural applications.

- Resistant to wear, ideal for long-term stability.

Cons:

- More expensive than SPF.

- Heavier, which may slow installation for large projects.

- Can split if over-nailed due to its density.

Price (Approximate): $4.50–$6.50 per 8-foot stud.

3. Whitewood

Whitewood is a term often used for SPF or similar light-colored softwoods, but it may also refer to specific species like tulip poplar. It’s marketed for its clean appearance and affordability.

Characteristics:

- Color: Very light, almost white, with minimal grain variation.

- Density: Low to moderate, similar to SPF.

- Grain: Generally straight with fewer knots, offering a cleaner look.

- Workability: Soft and easy to work with, but may not hold nails as securely as denser woods.

- Warping: Less prone to warping than SPF in some cases, but quality varies.

Applications:

- Best for non-structural framing where appearance matters, such as exposed studs in a barndominium.

- Often used in DIY projects due to its aesthetic appeal.

Pros:

- Straighter and cleaner than standard SPF, reducing sorting time.

- Affordable, often priced similarly to SPF.

- Lightweight and easy to handle.

Cons:

- Less durable than SYP or Douglas Fir, akin to a “dry sponge” in extreme cases.

- May have inconsistent quality depending on the supplier.

- Limited strength for structural applications.

Price (Approximate): $3.75–$5.50 per 8-foot stud.

4. Douglas Fir

Douglas Fir is a strong, versatile softwood commonly used in structural applications but also suitable for non-load-bearing framing.

Characteristics:

- Color: Reddish-brown with a pronounced grain.

- Density: High, comparable to SYP, offering excellent strength.

- Grain: Can have knots, but higher-grade “prime” Douglas Fir is clearer.

- Workability: Harder to work with than SPF due to density, but holds fasteners well.

- Warping: Moderately resistant to warping, though not as stable as finger-jointed studs.

Applications:

- Used in both structural and non-structural framing, especially in the western United States.

- Suitable for projects requiring durability and a premium appearance.

Pros:

- Strong and durable, ideal for long-lasting framing.

- Attractive grain for exposed applications.

- Holds nails and screws securely.

Cons:

- More expensive than SPF or Whitewood.

- Heavier, increasing labor effort.

- Prime grades are harder to find and costlier.

Price (Approximate): $5.00–$7.00 per 8-foot stud.

5. Hemlock

Hemlock is a softwood often used in framing, though less common than SPF or SYP.

Characteristics:

- Color: Light brown to reddish.

- Density: Moderate, similar to SPF.

- Grain: Contains knots and can be prone to splitting.

- Workability: Splits easily when nailed, requiring pre-drilling in some cases.

- Warping: Susceptible to warping, similar to SPF.

Applications:

- Used for non-load-bearing framing where cost is a priority.

- Less common in regions with abundant SYP or SPF.

Pros:

- Affordable, often cheaper than SYP or Douglas Fir.

- Lightweight, easing installation.

Cons:

- Prone to splitting and warping, reducing reliability.

- Less aesthetically pleasing due to knots and blemishes.

Price (Approximate): $3.50–$5.00 per 8-foot stud.

6. Finger-Jointed Studs

Finger-jointed studs are made by gluing together short sections of wood with interlocking “finger” joints, creating a straight, stable product.

Characteristics:

- Color: Varies by species (often SPF or Whitewood).

- Density: Comparable to the base wood species.

- Grain: Consistent due to short segments, reducing natural defects.

- Workability: Easy to work with, similar to SPF or Whitewood.

- Warping: Highly resistant to warping due to randomized grain orientation and kiln-drying.

Applications:

- Ideal for non-load-bearing walls where straightness is critical.

- Gaining popularity for their stability and cost-effectiveness.

Pros:

- Dead straight, minimizing culling.

- Potentially stronger due to glue joints, if properly manufactured.

- Often cheaper than premium-grade lumber.

Cons:

- Availability varies by region.

- May not be as aesthetically pleasing for exposed applications.

- Quality depends on the adhesive used.

Price (Approximate): $3.00–$4.50 per 8-foot stud (can be less than standard SPF in some markets).

Lumber Grades for 2x4s

Lumber grades determine the quality and strength of 2x4s, impacting their suitability for framing. Softwood grades for dimensional lumber include:

- Stud Grade: Designed specifically for wall framing, both load-bearing and non-load-bearing. It allows knots and blemishes but ensures sufficient strength. Most 2x4s for framing are Stud grade.

- No. 2 Common: Widely used for framing, with larger knots and minor defects. Suitable for non-load-bearing walls but requires careful selection to avoid warped pieces.

- No. 1 Common: Higher quality with fewer defects, often used for appearance framing or structural applications.

- Prime: A premium designation indicating a clean appearance, though not necessarily higher strength. Prime Stud or No. 1 Common grades are ideal for visible framing.

For non-load-bearing walls, Stud or No. 2 Common grades are sufficient, balancing cost and functionality. However, lower grades may have issues like insufficient nailing surfaces (less than 1.5 inches) due to wane or knots, as noted by some builders.

Comparison Table of 2×4 Wood Types

| Wood Type | Strength | Warping Resistance | Workability | Cost (per 8-ft stud) | Best Use |

|---|---|---|---|---|---|

| SPF | Moderate | Low | High | $3.50–$5.00 | Non-load-bearing framing |

| SYP | High | High | Moderate | $4.50–$6.50 | Structural/non-structural framing |

| Whitewood | Low-Moderate | Moderate | High | $3.75–$5.50 | Non-structural, aesthetic framing |

| Douglas Fir | High | Moderate | Moderate | $5.00–$7.00 | Structural/non-structural framing |

| Hemlock | Moderate | Low | Low | $3.50–$5.00 | Budget non-load-bearing framing |

| Finger-Jointed Studs | Moderate | Very High | High | $3.00–$4.50 | Non-load-bearing, straight framing |

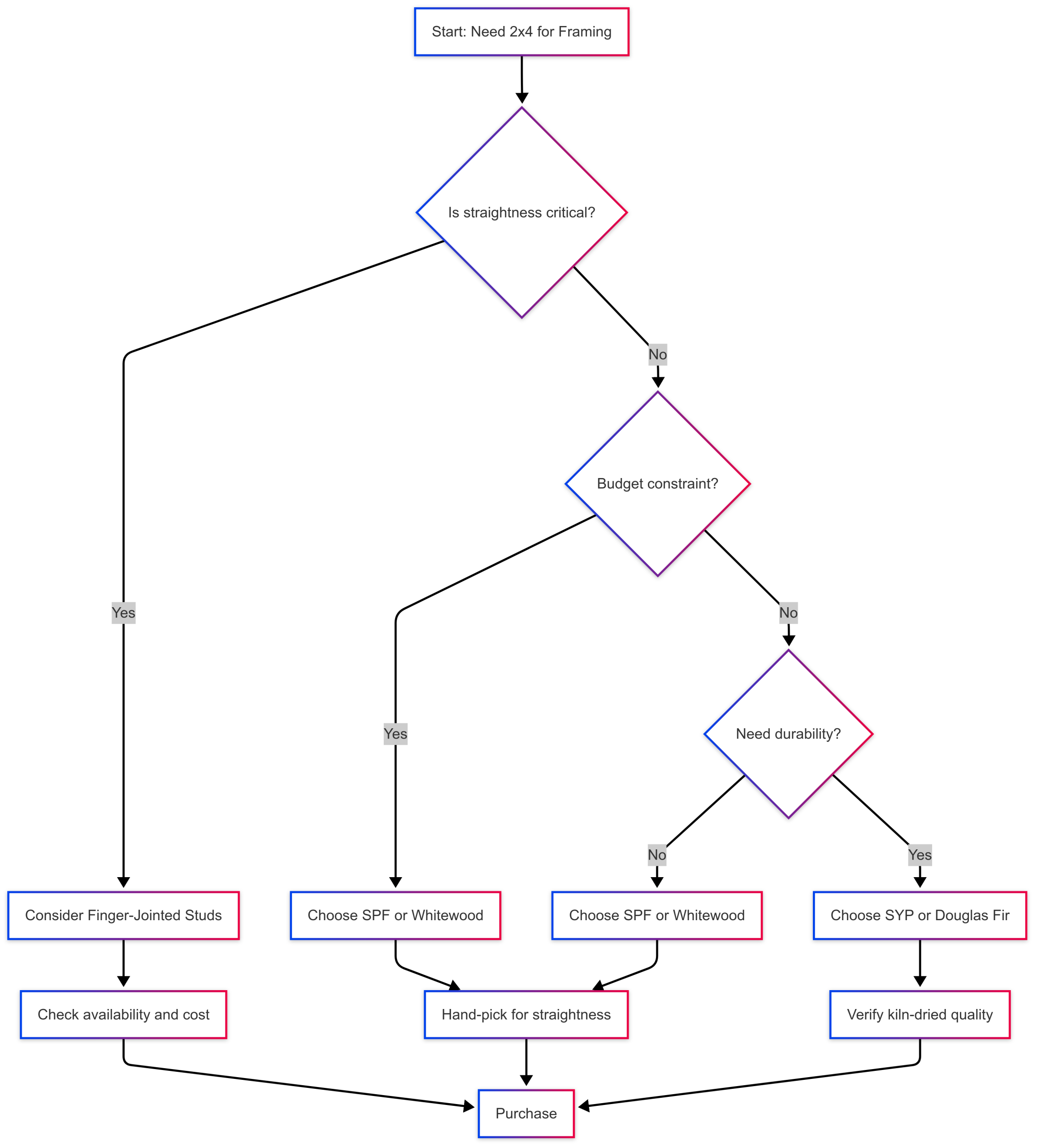

Decision Flow for Choosing 2×4 Wood

This flowchart helps you decide based on priorities like straightness, budget, and durability, guiding you to the optimal 2×4 type.

Recommendations for Barndominium Framing

For framing non-load-bearing bedroom walls in a barndominium, the following recommendations are based on the discussed wood types and user insights:

Best Overall Choice: Finger-Jointed Studs

- Why: Their superior straightness minimizes frustration and ensures consistent framing. They’re often cost-competitive with SPF and resist warping, making them ideal for long-term stability.

- Tip: Source from a reputable lumberyard to ensure quality glue joints. Check local availability, as they may not be stocked at all big-box stores.

Budget-Friendly Option: SPF or Whitewood

- Why: Both are affordable and widely available, suitable for non-load-bearing walls. Whitewood may offer a cleaner appearance if studs are exposed.

- Tip: Hand-pick each stud to avoid warped or defective pieces. Visit a lumberyard for better quality control or free delivery on bulk orders.

Premium Choice: Southern Yellow Pine

- Why: SYP’s strength and straightness make it a reliable choice, though it’s overkill for non-load-bearing walls. It’s ideal if you prioritize durability or live in a region where it’s abundant.

- Tip: Opt for No. 1 Common or Prime grades for fewer defects, and ensure proper storage to prevent moisture absorption.

Avoid: Hemlock, unless cost is the only concern, due to its tendency to split and warp.

Practical Tips for Selecting 2x4s

- Hand-Pick Lumber: At big-box stores like Home Depot or Menards, inspect each stud for straightness, avoiding bows, crooks, or twists. Look for tight knots rather than loose ones, which can fall out.

- Source from Lumberyards: Lumberyards often provide higher-quality stock and may deliver for free on bulk orders, saving time and ensuring better selection.

- Check Moisture Content: Ensure the wood is kiln-dried (marked “KD”) to reduce warping. A moisture meter can confirm levels below 19%.

- Calculate Quantities Precisely: Use project calculators to determine exact needs, adding 10% for waste or defects, as suggested by builders.

- Consider Engineered Alternatives: For future projects or if budget allows, explore Laminated Strand Lumber (LSL) studs for unmatched straightness, though they’re pricier ($6.00–$8.00 per 8-foot stud).

Common Lumber Defects to Avoid

When selecting 2x4s, watch for these defects, which can compromise framing quality:

- Bow: A curve along the face, making alignment difficult.

- Crook: A warp along the edge, affecting plumb walls.

- Cup: A hollow across the face, reducing nailing surface.

- Twist: Multiple warps, causing instability.

- Loose Knots: Can fall out, weakening the stud.

- Splits/Checks: Cracks that reduce structural integrity.

Cost Considerations

Lumber prices fluctuate based on region, supplier, and market conditions. As of recent data, finger-jointed studs may offer the best value for non-load-bearing framing, especially if purchased in bulk. For a barndominium with multiple bedrooms, expect to spend $500–$1,500 on 2x4s for framing, depending on the number of walls and wood type. Buying from lumberyards or ordering in bulk can reduce costs by 10–20% compared to big-box stores.

Conclusion

Choosing the right 2×4 wood for framing bedrooms in a barndominium involves balancing cost, straightness, and durability. Finger-jointed studs are the top recommendation for their stability and affordability, followed by SPF or Whitewood for budget-conscious projects, and SYP for premium applications. Always hand-pick lumber or source from a trusted lumberyard to ensure quality, and avoid defects like warping or loose knots. By understanding the properties of each wood type and applying practical selection strategies, you can achieve a sturdy, cost-effective framing solution that enhances your barndominium’s functionality and longevity.

For your next steps, visit a local lumberyard or retailer to compare options, and use the provided flowchart to guide your decision. With the right 2x4s, your framing project will be a seamless success.

Please share this Understanding different type 2×4 wood your friends and do a comment below about your feedback.

We will meet you on next article.

Until you can read, 5 Ways to Kill Roaches With Borax