Securing an existing 4×4 post to a cement surface is a critical task for homeowners looking to enhance safety and structural integrity, whether it’s for a porch railing, fence, or other outdoor structure. A loose post can pose significant safety risks, especially if it sways under pressure, as described in scenarios where posts move several inches when pushed. This guide provides a detailed, step-by-step approach to anchoring a 4×4 post to cement without disassembling existing structures, focusing on practical methods, tools, materials, and expert insights to ensure a robust and lasting solution.

Why Securing a 4×4 Post to Cement Matters

A loose 4×4 post on a cement surface, such as a porch or patio, can compromise safety and aesthetics. For instance, a porch railing post that moves 3 inches in either direction could fail if someone leans against it, potentially leading to injury or structural damage. Beyond safety, a secure post enhances the longevity of the structure, prevents further wear, and maintains the property’s visual appeal. Whether you’re addressing a wobbly fence post or a porch support, the goal is to achieve a stable, code-compliant installation that withstands lateral forces, weather, and time.

Understanding the Challenge

Before diving into solutions, it’s essential to assess the specific situation. Common issues with existing 4×4 posts include:

- Movement: Posts that sway due to inadequate anchoring or previous makeshift fixes like wooden shims.

- Surface Constraints: Cement slabs may vary in thickness (e.g., 4-6 inches for a porch), affecting anchor choice.

- Structural Role: Posts may be decorative or load-bearing, influencing the anchoring method.

- Preservation: The desire to avoid disassembling railings or other connected structures.

The primary challenge is finding a method that balances strength, simplicity, and minimal disruption. For example, a homeowner might consider a post base with anchors but find that standard hardware doesn’t fit existing holes, prompting exploration of alternative approaches.

Methods to Secure a 4×4 Post to Cement

There are three primary methods to anchor a 4×4 post to cement, each suited to different scenarios. Below, we explore these methods in detail, including their applications, pros, cons, and step-by-step instructions.

1. Surface Mounting with Post Bases

Surface mounting involves attaching a metal post base to the cement slab, into which the 4×4 post is secured. This method is ideal for posts with multiple points of support, such as those connected to a railing and a roof.

Applications:

- Porch or deck railings with interconnected supports.

- Posts supporting a canopy or overhang with additional bracing.

Pros:

- Relatively simple installation.

- Minimal disruption to existing structures.

- Wide availability of post bases (e.g., Simpson Strong-Tie, OZCO).

Cons:

- Not suitable for freestanding posts due to limited resistance to lateral forces.

- Requires precise drilling and anchoring.

- Potential for water pooling if not elevated.

Tools and Materials:

- Hammer drill with masonry bit (e.g., 3/8” or 1/2”).

- Concrete anchors (e.g., Tapcon screws, wedge anchors).

- Post base (e.g., Simpson ABU44Z, EPB44T).

- Galvanized screws or bolts.

- Level, tape measure, pencil, socket wrench.

- Safety gear (gloves, goggles).

Step-by-Step Instructions:

- Assess the Post: Confirm the post’s role (decorative or load-bearing) and ensure it’s plumb. If it’s load-bearing, consider jacking the structure slightly to align it properly.

- Select a Post Base: Choose a base compatible with a 4×4 post, such as the Simpson ABU44Z ($15-$20), which offers adjustable standoffs for moisture protection.

- Mark the Cement: Position the post base where the post will sit, ensuring alignment with the railing. Mark anchor holes with a pencil.

- Drill Holes: Using a hammer drill, bore holes into the cement to the depth specified by the anchor (e.g., 2-3 inches for 3/8” Tapcon screws). Clear debris with a vacuum.

- Install Anchors: Insert concrete anchors (e.g., 3/8” x 3” Tapcon screws, $0.50-$1 each) through the post base holes and tighten with a socket wrench.

- Attach the Post: Place the 4×4 post into the base, ensuring it’s plumb. Secure it with galvanized screws or bolts through the base’s side flanges.

- Check Stability: Test the post for movement. If it wobbles, verify anchor tightness and post alignment.

- Seal and Finish: Apply sealant around the base to prevent water infiltration. Paint or cover the base for aesthetics if desired.

Cost Estimate:

| Item | Price Range |

|---|---|

| Post Base (Simpson ABU44Z) | $15-$20 |

| Tapcon Screws (4-6) | $2-$5 |

| Galvanized Screws | $3-$5 |

| Total | $20-$30 |

User Reviews:

- John D., Homeowner: “Used the Simpson EPB44T for my porch railing. Easy to install with a hammer drill, and it’s rock-solid after a year.”

- Sarah M., DIYer: “The ABU44Z was adjustable, which helped with my uneven slab. Just wish it came with clearer instructions.”

2. Core and Set Method

This method involves drilling a core hole into the cement slab, inserting the 4×4 post, and filling the hole with concrete. It’s best for freestanding posts or those requiring maximum stability.

Applications:

- Fence posts on a concrete slab.

- Freestanding railings without additional supports.

Pros:

- Exceptional strength against lateral forces.

- Permanent, low-maintenance solution.

- Suitable for thick slabs (6+ inches).

Cons:

- Requires specialized equipment (core drill).

- Invasive, potentially damaging to thin slabs.

- Not ideal for load-bearing posts without engineering input.

Tools and Materials:

- Core drill (rental: $50-$100/day).

- Concrete mix (e.g., Quikrete, $5-$10/bag).

- Post level, tape measure, shovel.

- Protective gear, wheelbarrow for mixing.

Step-by-Step Instructions:

- Evaluate the Slab: Ensure the slab is thick enough (at least 6 inches) and free of utilities (use a concrete imaging service if unsure).

- Mark the Core: Outline a hole slightly larger than the 4×4 post (e.g., 6” diameter) where the post will sit.

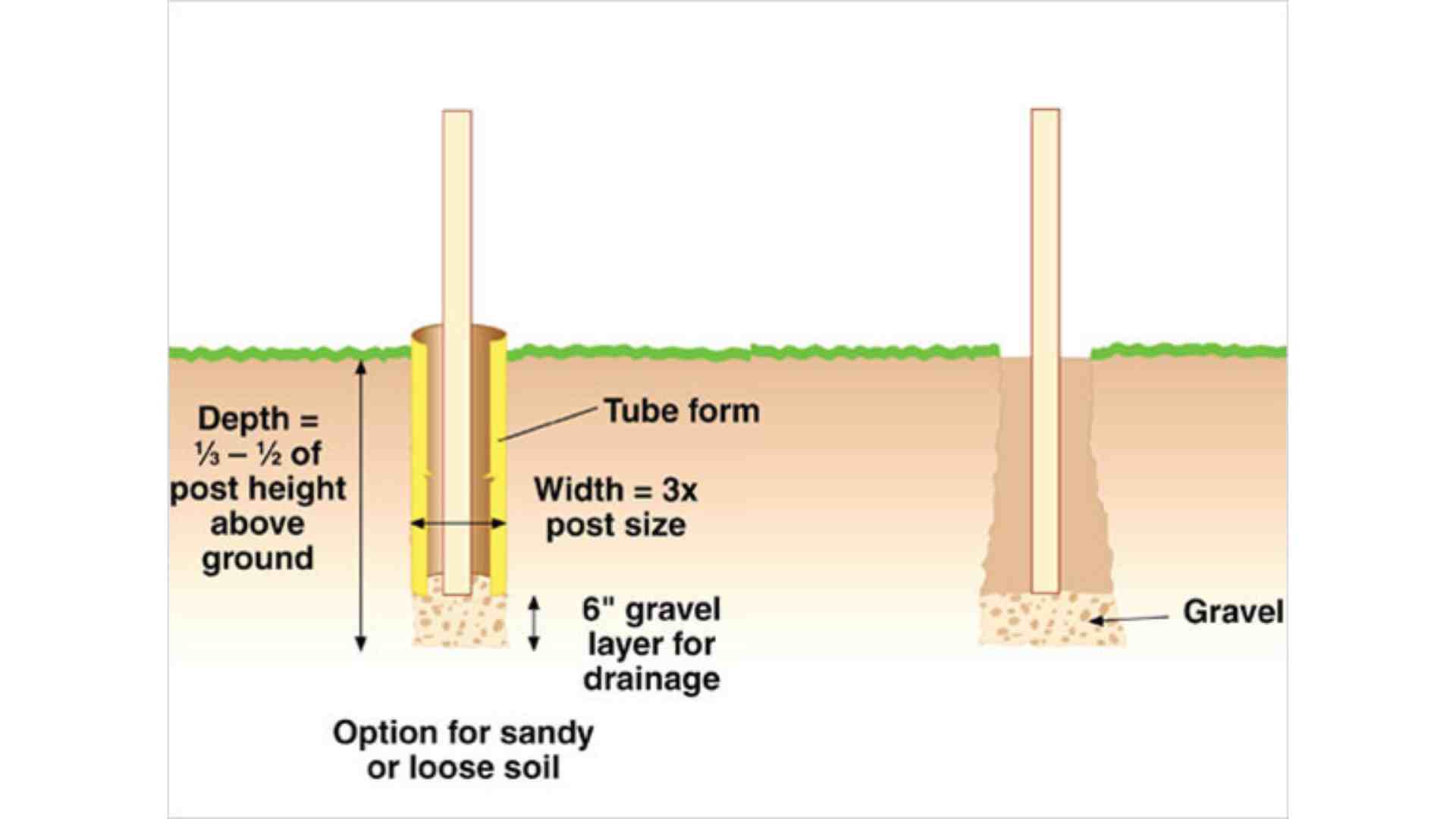

- Core the Slab: Rent a core drill and bore a hole one-third the post’s height (e.g., 24” for an 8’ post). Remove the core and clean the hole.

- Prepare the Post: Treat the post’s base with a preservative if not pressure-treated.

- Set the Post: Place the post in the hole, using a post level to ensure it’s plumb. Brace it with temporary supports.

- Pour Concrete: Mix concrete per instructions and pour it into the hole, filling to just below the slab’s surface. Smooth with a trowel.

- Cure and Test: Allow the concrete to cure for 24-48 hours. Remove braces and test the post’s stability.

- Finish: Seal the concrete edge and paint the post if desired.

Cost Estimate:

| Item | Price Range |

|---|---|

| Core Drill Rental | $50-$100 |

| Concrete Mix (1-2 bags) | $10-$20 |

| Preservative | $5-$10 |

| Total | $65-$130 |

User Reviews:

- Mike T., Contractor: “Cored a slab for fence posts, and they’re still standing after five years. Renting the drill was worth it.”

- Lisa R., Homeowner: “Tough to get the hole perfect, but the post is solid. Hire a pro if you’re not confident.”

Warning: Coring risks hitting utilities like plumbing or wiring. Always verify slab contents before drilling.

3. Side Mounting

Side mounting secures the post to the vertical face of a raised cement surface, such as steps or a porch edge, using sleeve anchors. It’s ideal for elevated structures where surface mounting isn’t feasible.

Applications:

- Posts on concrete steps or raised porches.

- Railings attached to a vertical cement face.

Pros:

- Strong for elevated installations.

- Less invasive than coring.

- Conceals anchors for a cleaner look.

Cons:

- Requires a raised surface (e.g., 12”+ height).

- Limited to specific configurations.

- Anchor failure possible in weak concrete.

Tools and Materials:

- Hammer drill with masonry bit.

- Sleeve anchors (e.g., 1/2” x 4”, $1-$2 each).

- Epoxy adhesive ($5-$10).

- Level, tape measure, wrench.

- Safety gear.

Step-by-Step Instructions:

- Assess the Surface: Ensure the cement face is at least 12” high and structurally sound.

- Position the Post: Hold the post against the vertical face, aligning it with the railing. Mark anchor points at least one-third of the post’s height below the top (e.g., 12” for a 36” post).

- Drill Holes: Bore holes into the cement to the anchor’s specified depth (e.g., 3” for 1/2” sleeve anchors). Clear debris.

- Apply Epoxy: Inject epoxy into the holes for added bond strength.

- Install Anchors: Insert sleeve anchors through the post and into the holes. Tighten with a wrench to expand the sleeve.

- Verify Alignment: Check the post’s plumbness and stability.

- Finish: Caulk around anchors and paint the post if needed.

Cost Estimate:

| Item | Price Range |

|---|---|

| Sleeve Anchors (2-4) | $2-$8 |

| Epoxy Adhesive | $5-$10 |

| Total | $7-$18 |

User Reviews:

- Tom S., DIYer: “Side-mounted my porch posts with sleeve anchors. Super sturdy, and the epoxy made it bombproof.”

- Emily P., Homeowner: “Looks clean, but drilling into old concrete was tricky. Had to redo one hole.”

Comparing the Methods

To choose the best method, consider your project’s specifics. Below is a comparison table:

| Method | Best For | Strength | Cost | Complexity | Aesthetics |

|---|---|---|---|---|---|

| Surface Mounting | Railings with multiple supports | Moderate | $20-$30 | Low | High |

| Core and Set | Freestanding posts | High | $65-$130 | High | Moderate |

| Side Mounting | Raised surfaces | Moderate | $7-$18 | Medium | High |

Recommendation: For a loose porch railing post with a connected structure, surface mounting is typically the best choice due to its simplicity and effectiveness. If the post is freestanding or on a thick slab, consider coring. Side mounting is niche but excellent for elevated installations.

Alternative Solutions

While the above methods are standard, some situations call for creative approaches:

- Steel Tube Reinforcement: Weld a steel tube to a base plate and bolt it to the cement, then slide the 4×4 over it. This is strong but requires welding skills.

- Notching and Lagging: Notch the post’s base to fit over a cement edge, securing it with lag bolts and epoxy. Ideal for posts near a slab’s edge.

- Rebar Anchoring: Drive rebar into the ground beside the slab and strap it to the post. This is less reliable and visually unappealing, as noted by experts.

These alternatives may work but often lack the reliability or code compliance of standard methods.

Tools and Equipment Guide

Here’s a breakdown of essential tools and their costs:

| Tool | Purpose | Price Range |

|---|---|---|

| Hammer Drill | Drilling into cement | $50-$150 (buy) or $20/day (rent) |

| Core Drill | Coring deep holes | $50-$100/day (rent) |

| Masonry Bit | For anchor holes | $5-$15 |

| Socket Wrench | Tightening anchors | $10-$20 |

| Post Level | Ensuring plumb alignment | $5-$10 |

Tip: Renting a hammer or core drill saves money for one-time projects. Check Home Depot or local rental yards.

Safety and Code Considerations

- Building Codes: Check local codes for railing height (typically 36-42”) and post spacing (4-6’). Freestanding posts may require engineering approval.

- Load Assessment: Verify if posts are load-bearing. If so, consult a structural engineer before anchoring.

- Moisture Protection: Use pressure-treated wood or standoff bases to prevent rot.

- Safety Gear: Wear goggles, gloves, and a dust mask when drilling or mixing concrete.

Common Mistakes to Avoid

- Using Inadequate Anchors: Small screws or mismatched anchors fail under lateral force.

- Ignoring Slab Thickness: Thin slabs (under 4”) may crack with heavy anchors.

- Skipping Leveling: Misaligned posts compromise stability and appearance.

- Neglecting Utilities: Drilling without checking for pipes or wires risks costly damage.

- Overlooking Maintenance: Unsealed bases or untreated wood rot quickly.

Expert Insights

- Contractor Tip: “Always use a standoff base to keep wood off the cement. Moisture is the enemy,” says Mike T., a 20-year contractor.

- Engineer’s Advice: “For load-bearing posts, don’t guess—get a structural analysis. A $200 consult can save thousands,” notes Sarah L., structural engineer.

Conclusion

| Scenario | Best Method |

|---|---|

| Porch Railings | Simpson ABU Post Base |

| Fence Posts | Epoxy + Rebar |

| Decorative Posts | OZCO Wrought Iron Base |

| Temporary Fix | Heavy-Duty Concrete Screws |

Securing an existing 4×4 post to cement is a manageable DIY project with the right approach. Surface mounting with a post base offers the best balance of ease and strength for most porch railings, costing $20-$30 and requiring basic tools. For freestanding posts, coring provides unmatched stability, though it’s pricier and more complex. Side mounting suits elevated surfaces but is less common. By choosing the appropriate method, verifying slab conditions, and following precise steps, you can eliminate wobble, enhance safety, and extend your structure’s lifespan.

For further guidance, consult local hardware stores or professionals, especially for load-bearing posts or complex setups. With careful planning and execution, your 4×4 post will stand firm for years to come.

Please share this How to secure existing 4×4 post to cement? your friends and do a comment below about your feedback.

We will meet you on next article.

Until you can read, Do You Need to Vent a Microwave?