Drill bits are indispensable tools for anyone engaging in DIY projects, woodworking, metalworking, or construction. Whether you’re mounting a shelf, installing wiring, or building furniture, selecting the right drill bit ensures precision, efficiency, and safety. With a vast array of drill bit types designed for specific materials and tasks, navigating the options can be daunting. This guide explores the various drill bit types, their construction, materials, applications, and maintenance tips, empowering you to choose the perfect bit for your project.

What Are Drill Bits?

Drill bits are cutting tools attached to a power drill or drill press, designed to create holes or drive fasteners into materials like wood, metal, masonry, tile, glass, and plastic. Each bit is engineered with specific features to suit different materials and applications, ensuring clean, accurate holes or secure fastening. Understanding the anatomy, materials, and types of drill bits is key to achieving professional results.

Drill Bit Anatomy and Construction

Before diving into specific types, let’s break down the essential components of a drill bit:

- Point: The tip of the bit that initiates cutting. It includes:

- Spur: A central point that anchors the bit, ensuring precise positioning.

- Cutting Lip: The edges that remove material as the bit rotates.

- Flutes: Spiral or straight grooves that channel debris (chips, dust) out of the hole, preventing clogging.

- Shank: The end that fits into the drill’s chuck, securing the bit. Common shank types include:

- Round Shank: Centers the bit accurately in the chuck.

- Hex Shank: Flat-sided for a secure grip, often used in quick-change chucks.

- SDS Shank: Slotted for hammer drills, allowing forward-backward movement.

- Body: The main structure, varying in diameter and length depending on the hole size and depth required.

The chuck—the drill’s clamping mechanism—holds the shank. Common chuck sizes are 3/8-inch and 1/2-inch for home drills, with larger 5/8-inch or 3/4-inch chucks found in industrial models. The bit’s point angle (e.g., 118° for soft materials, 135° for harder ones) influences its cutting efficiency and suitability for specific materials.

Drill Bit Materials and Finishes

The material and coating of a drill bit determine its durability, heat resistance, and performance. Here’s a look at common options:

| Material/Finish | Best For | Key Features |

|---|---|---|

| High-Speed Steel (HSS) | Wood, soft metals, fiberglass, PVC | Affordable, versatile, suitable for general-purpose drilling. |

| Black Oxide-Coated HSS | Hardwood, softwood, PVC, fiberglass, steel | Resists corrosion, enhances durability, retains lubricants. |

| Titanium-Coated HSS | Hardwood, softwood, PVC, fiberglass, steel | Reduces friction, stays sharp longer, tougher than black oxide. |

| Cobalt | Stainless steel, hard metals, aluminum | High heat resistance, abrasion resistance, ideal for tough metals. |

| Carbide-Tipped | Concrete, tile, masonry | Extremely sharp, long-lasting, withstands heavy-duty use. |

| Bi-Metal | Wood, light metal, PVC | Fast, smooth cutting with reduced vibration. |

| Diamond-Coated | Glass, sea glass, rocks, minerals | Ideal for brittle materials, ensures clean cuts without cracking. |

| Tungsten Carbide | Masonry, hard metals | One of the hardest materials, used for extreme durability. |

Note: Always match the bit material to the workpiece. For example, cobalt bits excel in stainless steel, while carbide-tipped bits are best for concrete.

Types of Drill Bits and Their Uses

Below is a detailed exploration of the most common drill bit types, their applications, and ideal use cases.

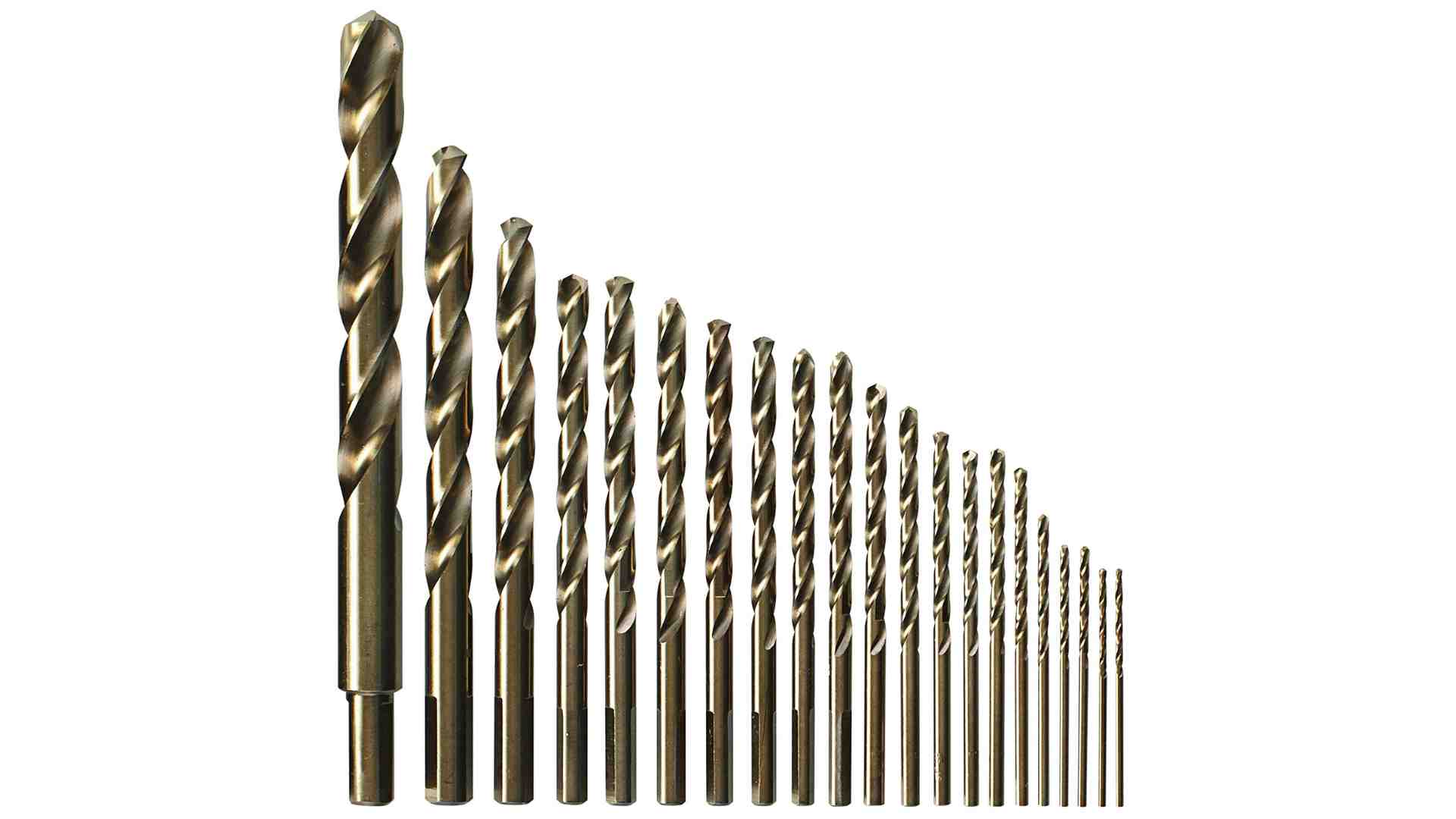

1. Twist Drill Bits

- Best For: General-purpose drilling in wood, plastic, light metal, ceramic, masonry.

- Features: Cylindrical with spiral flutes for debris removal, available in sizes up to 1 inch in diameter.

- Use Case: Drilling pilot holes for screws, home repairs, or maintenance tasks.

- Why Choose?: Their versatility makes them a staple in every toolbox. HSS or titanium-coated versions enhance performance.

2. Brad-Point Drill Bits

- Best For: Precision woodworking, furniture making, cabinetry.

- Features: Sharp central brad for accurate positioning, wide flutes for clean chip removal, W-shaped spurs for clean exit holes.

- Use Case: Drilling holes for dowels, cabinet hardware, or decorative woodwork.

- Why Choose?: Produces clean, splinter-free holes, ideal for visible woodworking projects.

3. Auger Drill Bits

- Best For: Deep, clean holes in thick wood, large woodworking projects.

- Features: Screw tip pulls the bit through wood, large flutes clear chips, lengths up to 18 inches.

- Use Case: Drilling for plumbing, electrical conduit, or heavy-duty framing.

- Why Choose?: Requires less pressure, ensuring straight, deep holes with minimal effort.

4. Spade Drill Bits

- Best For: Large-diameter holes in wood, framing, electrical, plumbing.

- Features: Flat, paddle-like blade with a sharp center point, sizes up to 1-1/2 inches.

- Use Case: Boring holes for wiring or pipe passages in studs.

- Why Choose?: Fast and cost-effective for rough cuts, though edges may splinter.

5. Forstner Drill Bits

- Best For: Flat-bottomed, clean holes in wood, woodworking, cabinetry.

- Features: Cylindrical with a central spur, cuts precise, smooth holes, best used in a drill press.

- Use Case: Installing hinges, dowels, or creating decorative inlays.

- Why Choose?: Delivers professional-grade, flat-bottomed holes for precise joinery.

6. Countersink Drill Bits

- Best For: Preparing wood for flush or recessed screws, general woodworking.

- Features: Cone-shaped to create a bevel for screw heads, often includes a pilot hole drill.

- Use Case: Cabinetry, furniture assembly, or any project requiring flush fasteners.

- Why Choose?: Combines pilot hole and countersink in one step, saving time.

7. Installer Drill Bits

- Best For: Running wiring through walls, woodworking, cabinetry.

- Features: Long (up to 18 inches), with a side hole for pulling wires.

- Use Case: Installing electrical, security, or entertainment systems.

- Why Choose?: Simplifies threading wires through walls or floors.

8. Step Drill Bits

- Best For: Multiple hole sizes in thin metal, wood, plastic.

- Features: Stepped, cone-shaped design, titanium-nitride coating for heat resistance.

- Use Case: Drilling pilot holes in sheet metal or enlarging existing holes.

- Why Choose?: Eliminates the need to switch bits for different diameters.

9. Tile Drill Bits

- Best For: Ceramic, porcelain tiles, flooring, backsplashes.

- Features: Carbide or diamond-tipped, arrow-shaped for chip-free cuts.

- Use Case: Tile installations or renovations.

- Why Choose?: Prevents cracking or chipping, ensuring clean holes.

10. Glass Drill Bits

- Best For: Non-tempered glass, ceramic.

- Features: Spear-shaped, carbide-tipped, used at low speeds with coolant.

- Use Case: DIY glass projects, mirror installations.

- Why Choose?: Minimizes shattering risks for delicate materials.

11. Masonry Drill Bits

- Best For: Concrete, brick, stone, masonry.

- Features: Tungsten carbide tip, used with hammer drills for impact.

- Use Case: Installing anchors, mounting fixtures in walls.

- Why Choose?: Built for durability in tough materials.

12. Hole Saw Drill Bits

- Best For: Large-diameter holes in wood, metal, tile, masonry.

- Features: Circular blade with a pilot bit, sizes from 3/4 to 6 inches.

- Use Case: Installing door hardware, plumbing, or electrical fittings.

- Why Choose?: Cuts large, clean holes while leaving the core intact.

13. Screwdriver Drill Bits

- Best For: Driving or removing screws, various materials.

- Features: Tips like Phillips, Torx, square, or slotted to match screw heads.

- Use Case: Furniture assembly, renovations, machine work.

- Why Choose?: Versatile for fastening tasks with drills or impact drivers.

14. Coring Drill Bits

- Best For: Large holes in masonry, concrete, brick.

- Features: Hollow core removes a cylinder of material, used with rotary hammers.

- Use Case: HVAC ducts, plumbing, or structural reinforcements.

- Why Choose?: Efficient for heavy-duty construction projects.

15. Specialty Drill Bits

- Examples:

- Pocket Hole Bits: Drill angled holes for wood joints.

- Drill Saw Bits: Cut irregular shapes in wood or metal.

- Scaling Chisels: Chip away masonry in hammer drills.

- Self-Centering Bits: Ensure accurate screw holes for hardware.

- Use Case: Niche tasks like joinery, chiseling, or tight-space drilling.

- Why Choose?: Tailored for specific, high-precision jobs.

Drill Bit Shank Types

The shank connects the bit to the drill’s chuck, and its design affects compatibility and performance:

| Shank Type | Best For | Features |

|---|---|---|

| Hex Shank | Screwdrivers, quick-change chucks | Six-sided for secure grip, ideal for impact drivers. |

| SDS Plus/Max | Hammer drills, masonry | Slotted for heavy-duty impact, allows bit movement. |

| Straight Shank | Standard drills | Smooth, round, fits keyed or keyless chucks (10-13mm). |

| Threaded Shank | Compact drills, grinders | Screws into chuck-less tools, ideal for tight spaces. |

Choosing the Right Drill Bit

Selecting the appropriate drill bit involves considering:

Material:

- Wood: Brad-point, auger, or spade bits for clean, deep holes.

- Metal: Cobalt or HSS bits for durability and heat resistance.

- Masonry: Carbide-tipped or SDS bits for impact drilling.

- Tile/Glass: Diamond or carbide-tipped bits for chip-free cuts.

Hole Size and Depth:

- Match the bit diameter to the fastener or anchor size (e.g., 6mm for red wall plugs, 16mm for M10 bolts).

- Use longer bits (e.g., auger, installer) for deep holes.

| Screw Size | Pilot Hole Size (Wood) |

|---|---|

| #6 | 3/32″ |

| #8 | 1/8″ |

| #10 | 9/64″ |

| 1/4″ | 7/32″ |

Drill Type:

- Ensure shank compatibility with your drill’s chuck (e.g., SDS for hammer drills).

- Use a drill press for Forstner bits to maintain control.

Project Requirements:

- Precision tasks (e.g., cabinetry) need brad-point or Forstner bits.

- Rough cuts (e.g., framing) suit spade or hole saw bits.

Tip: Invest in a multi-purpose drill bit set for versatility, including sizes from 1/16 to 1/2 inch, and add specialty bits as needed.

Drill Bit Maintenance

Proper care extends the life of your drill bits and ensures safety:

- Cleaning: Wipe bits with a dry cloth or toothbrush to remove debris after use.

- Cooling: Let bits cool naturally post-drilling to prevent warping.

- Sharpening: Use a drill bit sharpener or grinding tools for dull bits to maintain cutting efficiency.

- Storage: Store in a labeled case to prevent nicks or scratches. Mark sizes for quick identification.

- Inspection: Replace damaged or worn bits to avoid workpiece damage or injury.

- Lubrication: Apply cutting oil when drilling metal to reduce heat and friction.

Pro Tip: Dull bits increase drilling time and risk injury. Regular sharpening is a worthwhile investment.

Specifications and Pricing

Here’s a sample of popular drill bit types, their specifications, and approximate prices (based on common retail data):

| Drill Bit Type | Size Range | Material | Price Range (USD) |

|---|---|---|---|

| Twist Drill Bit Set | 1/16”–1/2” | HSS, Titanium | $10–$50 (10–20 pieces) |

| Brad-Point Bit | 1/8”–1” | Carbon Steel | $5–$15 each |

| Auger Bit | 1/4”–1-1/2” | HSS | $10–$30 each |

| Spade Bit Set | 1/4”–1-1/2” | Carbon Steel | $15–$40 (6 pieces) |

| Forstner Bit | 1/4”–2” | HSS, Carbide | $8–$25 each |

| Masonry Bit | 1/8”–1” | Carbide-Tipped | $3–$20 each |

| Hole Saw Kit | 3/4”–6” | Bi-Metal, Carbide | $20–$100 (5–10 pieces) |

| Cobalt Bit Set | 1/16”–3/8” | Cobalt | $20–$80 (10–15 pieces) |

Note: Prices vary by brand (e.g., DeWalt, Bosch, Milwaukee) and retailer. Sets offer better value for frequent DIYers.

User Reviews and Insights

Based on community feedback from platforms like Reddit’s r/Tools and r/DIY:

- Twist Drill Bits: “I use HSS twist bits for most home projects. They’re cheap and get the job done for wood and thin metal.” – u/DIYFanatic

- Brad-Point Bits: “Switched to brad-point for my cabinet project, and the clean holes made all the difference. Worth the extra cost!” – u/WoodWizard

- Masonry Bits: “Carbide-tipped masonry bits with my hammer drill made quick work of concrete walls. Don’t skimp on quality here.” – u/HomeBuilder88

- Cobalt Bits: “Drilling stainless steel was a nightmare until I got cobalt bits. They stay sharp and don’t overheat.” – u/MetalMaverick

- Spade Bits: “Great for quick jobs like running cables, but they can tear up the wood if you’re not careful.” – u/ElectricianJoe

Common Complaints:

- Cheap bits dull quickly, especially on metal or masonry.

- Some users find specialty bits (e.g., Forstner) tricky without a drill press.

Recommendations:

- Brands like Bosch, DeWalt, and Irwin are praised for durability.

- Multi-material sets are ideal for beginners tackling varied projects.

Best Drill Bit Sets (Recommendations)

| Brand | Type | Price Range ($) | Best For |

|---|---|---|---|

| DEWALT Titanium | HSS Twist Set | 20−50 | General-purpose |

| Bosch Multi-Construction | Masonry & Wood | 30−70 | Home renovation |

| Milwaukee Shockwave | Impact-rated | 40−100 | Metal & heavy-duty |

| IRWIN Speedbore | Wood Spade Set | 15−40 | Carpentry |

Common FAQs

What’s the strongest drill bit?

Tungsten carbide bits are the hardest, ideal for masonry and tough metals.

Do colors indicate bit type?

Not always. Titanium-coated bits are often gold, black oxide is black, but colors vary by brand. Check the label for material and use.

When to use a pilot hole?

Drill pilot holes for screws in wood or metal to prevent splitting or stripping. Use a bit slightly smaller than the screw diameter.

Can I use masonry bits on metal?

Not recommended. Masonry bits are designed for impact drilling and may damage metal or dull quickly.

Are drill bits universal?

No. Bits must match the drill’s chuck size and type (e.g., SDS, hex). Check compatibility before buying.

Conclusion

Drill bits are the unsung heroes of any drilling project, transforming your power drill into a versatile tool for woodworking, metalworking, masonry, and more. From the versatile twist bit to the precision-driven Forstner bit, each type serves a unique purpose, ensuring you achieve clean, accurate results. By understanding their construction, materials, and applications, you can confidently select the right bit for your task, whether it’s hanging a picture frame or building a deck.

Invest in quality bits, maintain them properly, and keep a varied set on hand to tackle any project with ease. For more tool advice or to explore high-quality drill bits, visit trusted retailers like Home Depot, Lowe’s, or specialized suppliers like Findbuytool.

Please share this Different Drill Bit Types and Their Uses your friends and do a comment below about your feedback.

We will meet you on next article.

Until you can read, What Is the Echo Oil Mix Ratio Chart for String Trimmers