Understanding the floor load capacity of your commercial space is a critical aspect of ensuring safety, compliance, and operational efficiency. Whether you’re installing heavy machinery, redesigning a workspace, or simply ensuring your floors can handle the demands of your business, accurate load calculations are essential. This comprehensive guide will walk you through the process of calculating floor load capacity, explain the key concepts involved, and provide practical tools and examples to help you determine the weight limits of your floors. By the end, you’ll have a clear understanding of how to assess your floor’s capabilities and make informed decisions for your business.

What Is Floor Load Capacity?

Floor load capacity refers to the maximum weight a floor can safely support over a given area without risking structural failure. In the United States, this is typically measured in pounds per square foot (psf), while in other regions, it might be expressed in kilonewtons per square meter (kN/m²). This capacity encompasses two primary types of loads: dead loads and live loads.

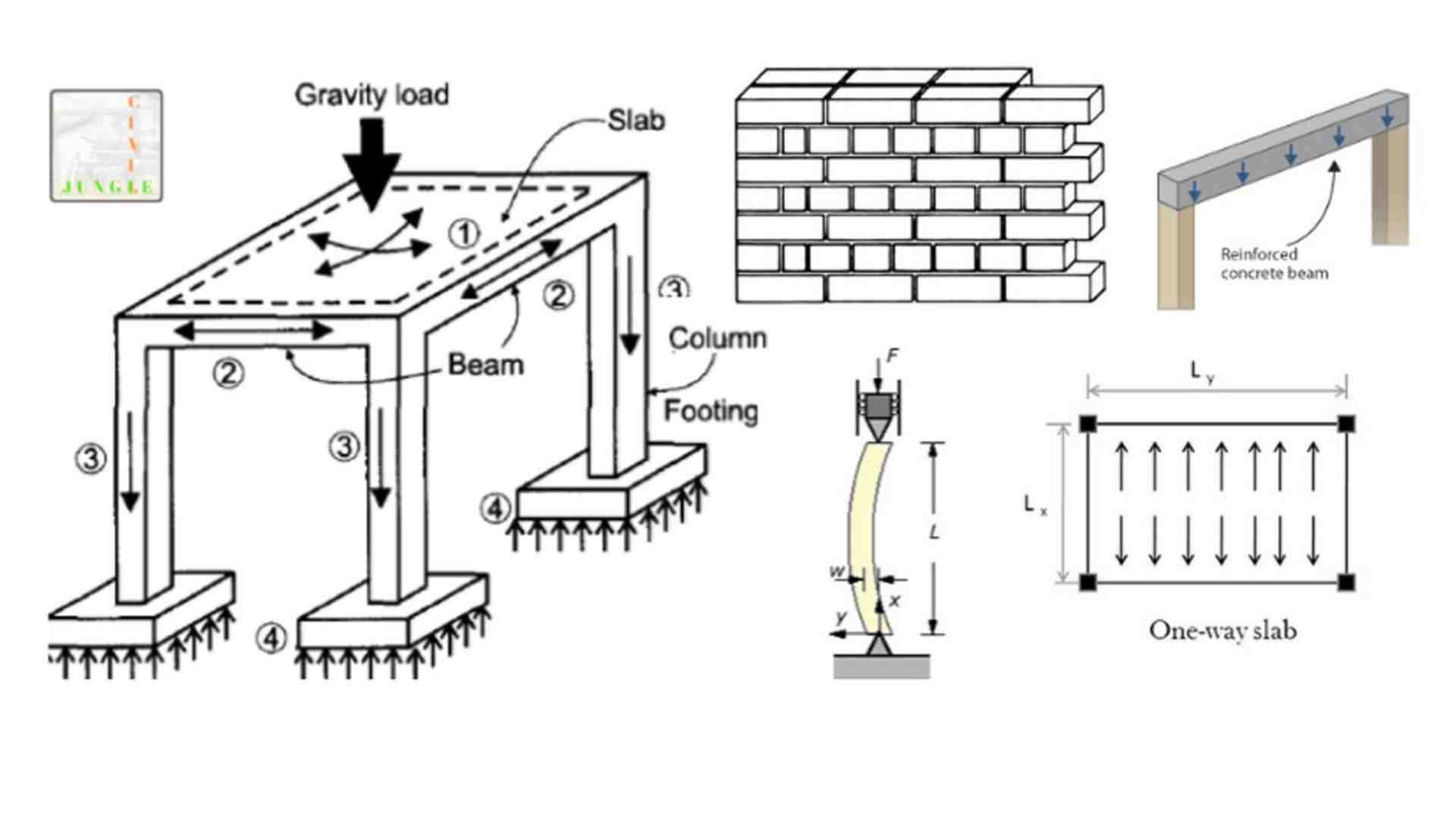

- Dead Loads: These are static, permanent weights that the floor must always support. Examples include the weight of the flooring materials (e.g., wood, concrete, or tiles), walls, beams, and any fixed fixtures like built-in shelving or HVAC systems.

- Live Loads: These are variable, dynamic weights that change depending on the use of the space. They include people, furniture, equipment, and anything else that can be moved or added temporarily.

The total floor load capacity is the sum of these two load types, and it’s determined by the structural components of the floor—most notably the joists, beams, and columns—along with the materials used in construction. Knowing this capacity ensures your floors can handle the demands of your business without buckling, cracking, or causing costly repairs.

Why Calculating Floor Load Capacity Matters

For any business, understanding floor load capacity is not just a technical exercise—it’s a practical necessity. Here’s why it’s so important:

- Safety: Overloading a floor can lead to structural failure, endangering employees, customers, and property. Accurate calculations prevent accidents like collapsing floors or cracked joists.

- Equipment Installation: If your business relies on heavy machinery—such as a rolling mill, industrial oven, or commercial refrigerator—the floor must support its weight without compromising stability.

- Cost Efficiency: Exceeding load limits can result in damage that requires expensive repairs. Knowing your floor’s capacity helps you avoid these unnecessary costs.

- Compliance: Local building codes set minimum standards for floor load capacity. Failing to meet these requirements can lead to fines, legal issues, or forced closures.

- Design Optimization: Proper load calculations allow you to maximize your space’s potential without overbuilding, saving on construction costs while ensuring safety.

Whether you’re setting up a gym with weightlifting equipment, a warehouse with storage racks, or an office with filing cabinets, knowing your floor’s limits is the foundation of a successful operation.

Types of Loads: Dead vs. Live

To calculate floor load capacity accurately, you need to distinguish between dead and live loads and understand how they interact.

Dead Loads

Dead loads are the constant weights inherent to the structure itself. These include:

- Flooring Materials: For example, a wooden floor with vinyl overlay might weigh 8-10 psf, while a concrete slab could weigh significantly more (e.g., 75-100 psf depending on thickness).

- Structural Components: Joists, beams, and columns contribute to the dead load. A typical 2×8 wooden joist at 16-inch spacing might add 2-3 psf.

- Permanent Fixtures: Built-in counters, walls, or plumbing systems also count.

For instance, in a commercial kitchen, the dead load might include the weight of tile flooring (10 psf), a gypsum ceiling (2.5 psf), and the joists (2 psf), totaling around 14.5 psf.

Live Loads

Live loads fluctuate based on how the space is used. Examples include:

- People: A crowded room might impose 50-100 psf, depending on occupancy.

- Equipment: A 14-ton rolling mill or a 675-lb whirlpool tub adds significant live load in a concentrated area.

- Furniture: Desks, chairs, and shelving units contribute to the total.

Building codes often specify minimum live load requirements. For example, the International Residential Code (IRC) mandates:

- Non-sleeping rooms: 40 psf

- Sleeping rooms: 30 psf

- Commercial spaces: 50-100 psf, depending on use (e.g., light commercial vs. heavy industrial)

Understanding these distinctions allows you to calculate the total load your floor must support and compare it to its capacity.

Building Codes and Standards

Before diving into calculations, familiarize yourself with local building codes, which dictate minimum load requirements and safety standards. In the U.S., most codes are based on the IRC or the International Building Code (IBC). These codes ensure floors can handle typical loads while maintaining structural integrity.

Key Code Requirements

- Minimum Live Loads: As noted, non-sleeping areas require 40 psf, while commercial spaces might demand 50 psf or more.

- Deflection Limits: Floors must not bend excessively under load. The IRC specifies a deflection limit of L/360, where “L” is the span length in inches. For a 10-foot (120-inch) span, the floor can deflect no more than 120/360 = 0.33 inches.

- Safety Factors: Codes often include a safety margin (e.g., 1.5x the expected load) to account for unexpected stresses.

Check with your local municipality for specific requirements, as they may vary based on climate, seismic activity, or intended use. For complex projects, consulting a structural engineer ensures compliance and safety.

Tools for Calculating Floor Load Capacity

Calculating floor load capacity involves several measurements and tools. Here’s what you’ll need:

Measurements:

- Span: The distance between supports (e.g., walls or beams) that the joists cross.

- Joist Size and Spacing: Common sizes include 2×6, 2×8, or 2×10, spaced 12, 16, or 24 inches on center (oc).

- Floor Area: The total square footage of the space.

- Lumber Grade and Species: Look for stamps on joists (e.g., “Douglas Fir #1”) to determine strength.

Span Tables:

- These tables, provided by organizations like the American Wood Council (AWC), list the maximum load a joist can support based on its size, spacing, and species. They include:

- Fb Value: Bending strength (e.g., 1,495 for a 2×6 Douglas Fir).

- E Value: Stiffness (e.g., 1,900,000 psi).

Floor Load Calculators:

- Online tools simplify the process by automating calculations. Popular options include:

- Omni Calculator (omnicalculator.com/construction/floor-joist)

- MEICON Floor Loading Calculator (meicon.net/floor-loading-occupancy-calculator)

- Calculator Academy (calculator.academy/floor-weight-capacity-calculator)

These tools require inputs like floor area and capacity per unit area, then output the total weight capacity.

Step-by-Step Guide to Calculating Floor Load Capacity

Let’s break down the process into actionable steps, using examples to illustrate.

Step 1: Gather Structural Information

Measure your floor’s key components:

- Span: Measure the unsupported length of the joists.

- Joist Size and Spacing: Check the dimensions (e.g., 2×8) and spacing (e.g., 16 inches oc).

- Lumber Type: Identify the species and grade from stamps or blueprints.

Example: A commercial kitchen has 2×8 Douglas Fir joists, spaced 16 inches oc, spanning 10 feet.

Step 2: Determine Dead Load

Calculate the weight of permanent elements:

- Flooring: Vinyl over wood (8 psf)

- Ceiling: Gypsum board (2.5 psf)

- Joists: 2 psf

- Total Dead Load: 8 + 2.5 + 2 = 12.5 psf

Step 3: Consult Span Tables

Using a span table (e.g., from the AWC), find the joist’s capacity:

- For 2×8 Douglas Fir #1, 16-inch spacing, 10-foot span:

- Live Load: 40 psf

- Dead Load: 10 psf

- Fb: 1,495

- E: 1,900,000

This indicates the joists can support 40 psf live load and 10 psf dead load, totaling 50 psf. Since the actual dead load (12.5 psf) exceeds 10 psf, adjust the live load capacity: 50 – 12.5 = 37.5 psf.

Step 4: Calculate Total Capacity

Multiply the capacity per square foot by the floor area:

- Area: 10 ft x 11 ft = 110 sq ft

- Total Capacity: 110 x 50 = 5,500 lbs (with 12.5 psf dead load, live load capacity is 4,125 lbs).

Step 5: Compare to Intended Load

If you’re installing a 1,000-lb oven (live load), check if it fits:

- Live Load: 1,000 / 110 = 9.1 psf

- Total Load: 9.1 + 12.5 = 21.6 psf

- Result: 21.6 psf < 50 psf, so the floor can handle it.

For concentrated loads (e.g., a machine on a small footprint), calculate the psf over that area and ensure it doesn’t exceed the joist’s capacity.

Practical Examples

Example 1: Commercial Kitchen Oven

- Floor: 2×8 joists, 16-inch oc, 10-ft span, Douglas Fir #1

- Dead Load: 12.5 psf

- Live Load Capacity: 37.5 psf

- Oven: 1,000 lbs over 10 sq ft = 100 psf

- Result: 100 psf exceeds 37.5 psf. Reinforce the floor or consult an engineer.

Example 2: Warehouse Rolling Mill

- Machine: 14 tons (28,000 lbs)

- Footprint: 8 ft x 12 ft = 96 sq ft

- Load: 28,000 / 96 = 291.7 psf

- Floor Rating: 20 kN/m² (≈ 417 psf)

- Result: 291.7 psf < 417 psf, but operational vibrations require an engineer’s review.

Example 3: Bathroom Whirlpool Tub

- Tub: 675 lbs + 180 lbs mortar + 200 lbs person = 1,055 lbs

- Area: 60” x 32” = 13.33 sq ft

- Load: 1,055 / 13.33 = 79.2 psf

- Floor: 2×8 joists, 16-inch oc, 9.5-ft span

- Capacity: 40 psf live + 10 psf dead = 50 psf

- Result: 79.2 psf > 50 psf. Reinforcement needed.

Using Span Tables and Calculators

Span Table Example

For 2×8 Douglas Fir #1, 16-inch oc, 11-ft span:

- 30 psf live + 10 psf dead: Fb = 1,315, E = 1,800,000

- 40 psf live + 10 psf dead: Fb = 1,644, E = 2,400,000

- Use the highest values your joists meet to determine safe limits.

Calculator Example

Input into a tool like Omni Calculator:

- Area: 1,200 sq ft

- Capacity: 25 psf

- Result: 1,200 x 25 = 30,000 lbs

When to Call a Structural Engineer

While DIY calculations are useful, certain scenarios require professional expertise:

- Heavy Machinery: Vibrations or concentrated loads (e.g., a 14-ton mill) need dynamic analysis.

- Uncertain Joist Condition: Cuts, damage, or unknown lumber grades affect capacity.

- Code Compliance: Engineers ensure adherence to local regulations.

- Reinforcement: If loads exceed capacity, they can design solutions like additional joists or beams.

Conclusion

Calculating floor load capacity is a vital skill for any business owner or manager looking to optimize their space safely and efficiently. By understanding dead and live loads, consulting building codes, and using tools like span tables and calculators, you can estimate your floor’s limits with confidence. Whether it’s a small office upgrade or a major industrial installation, these calculations protect your investment and ensure safety. For complex projects or high-stakes equipment, partnering with a structural engineer is the best way to guarantee success. With this knowledge, you’re equipped to make informed decisions and keep your business on solid ground.

Please share this Calculating Floor Load Capacity for Your Business your friends and do a comment below about your feedback.

We will meet you on next article.

Until you can read, 15 Ways to Reuse Jack O’ Lanterns in Your Garden